how does a brake line compression fitting work

When placed on a. Compression brakes also known as Jake brakes work by cracking open an exhaust valve or 2 a few hundredths of an inch or so.

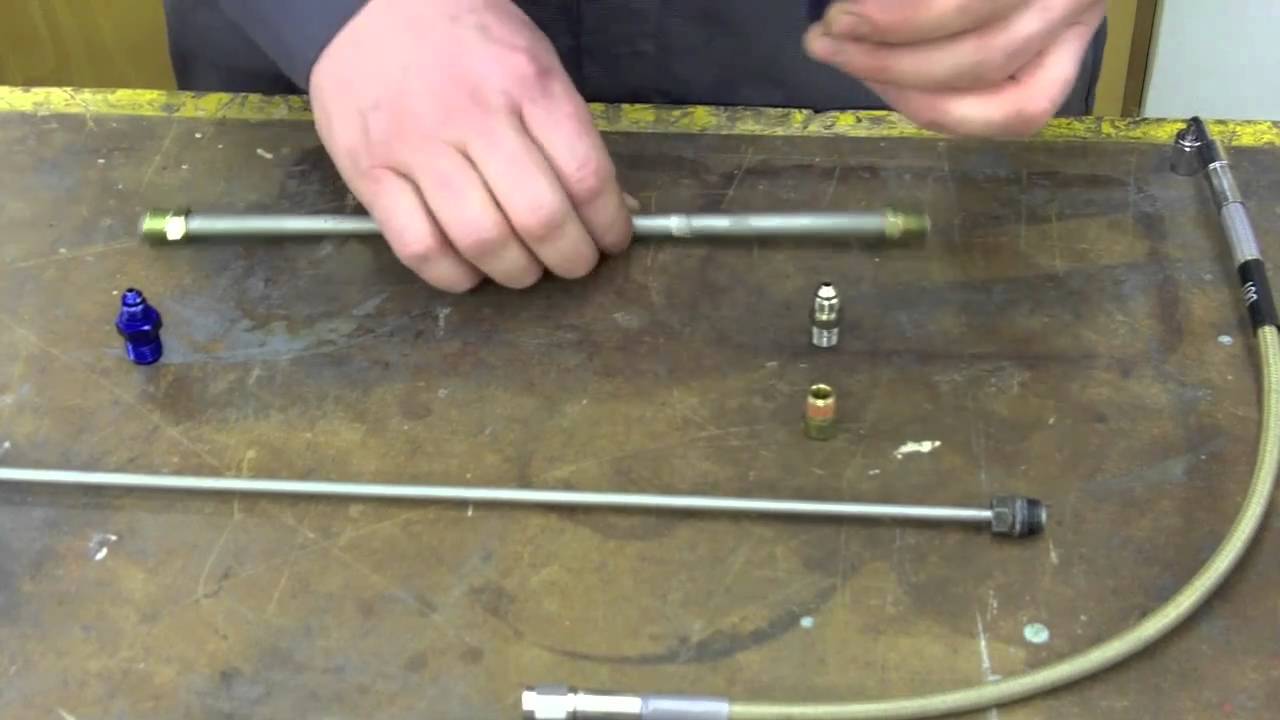

Connecting Brake Lines With A Compression Fitting Youtube

Any vehicle that is not driving on public roads and is not driving at high speeds can use compression fittings for brake repairs.

. Typically the procedure for tightening a compression fitting is specified using the rotation of the nut as the key metric rather than torque. Buy online for free next day delivery or same day pickup at a store near you. The corrosion decreases the commpressive strength and physical diameter of the line.

This is very dangerous. Compression fittings are used to join two pieces of brake line together. The pressure running through brake lines is extremely high.

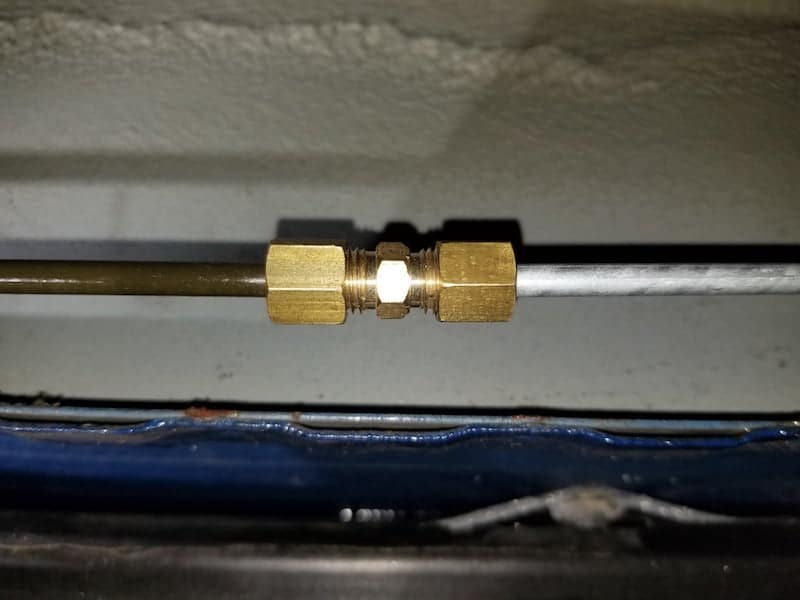

Compression fittings are used to join two pieces of brake line together. As the nut is tightened the compression ring is pressed into the seat causing it to compress against the pipe and the compression nut providing a watertight connection. Several states have made the use of compression fittings on passenger cars illegal for this very reason.

This form of repair is common because of the idea that the fitting prevents leakage. The ring the nut and the seat. Answer 1 of 3.

Unfortunately using brake line compression fittings presents multiple problems. With the introduction of quick-connect style fittings to the water treatment industry the compression fitting was used less frequently but its still a great fitting that can handle high pressure and give you a reliable. When placed on the brake cord the fitting makes a tight connection.

When placed on a brake line the fitting creates a tightened joint. You cannot under any circumstances use compression fittings to repair the lines on a public transportation vehicle. Compression fittings are used to join two pieces of brake line together.

A few have a dedicated smaller valve. This form of repair is common because of the idea that the fitting prevents leakage. Compression fittings are NOT designed to hold the kinds of pressures that are seen in an automotive brake system.

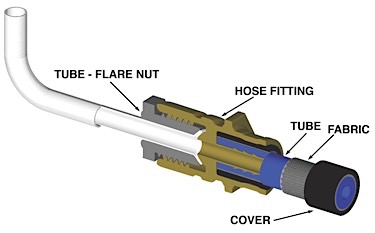

If the compression fitting is to be blown towards this type of vehicle the low speed will allow the driver to roll slowly until it stops. Compression assembly consists of a nut and a sleeve. A compression fitting is a type of coupling used to connect two pipes or a pipe to a fixture or valve.

Many states have banned the use of this repair on passenger vehicles too. Compression fittings typically are not capable of withstanding this high amount of pressure. Go back and demand your.

Compression fittings can splice pieces or sections of steel brake line together to create a seal between the two sections. You cannot under any circumstances use compression fittings to repair the lines on a public transportation vehicle. Compression fittings arent designed to handle the hydraulic pressure a brake system is imposses.

It is a metal object which connects one component of the coupling to another usually some type of pipe to create a waterproof seal. So the line cant blow out of the fitting. Compression fittings can splice pieces or sections of steel brake line together to create a seal between the two sections.

How do compression fittings work on brake lines. The compression fitting is comprised of a nut and a ferrule. In particular this accessory usually connects two parts of the brake line and prevents leakage.

The piston now has to work to move upwards during the compression stroke however at the top of the compression. A compression fitting only retains its strength if the line it is on is absulutely stable. The pressure running through brake lines is extremely high.

These components are compressed so that they can keep the connection watertight or in other words leak-free. This form of repair is common because of the idea that the fitting prevents leakage. The compression fitting is comprised of a nut and a ferrule.

About Press Copyright Contact us Creators Advertise Developers Terms Privacy Policy Safety How YouTube works Test new features Press Copyright Contact us Creators. 15 off orders over 100 Free Ground Shipping. A compression fitting will handle 300-500 psi just fine but a modern brake system can have pressures just in normal stopping of 1200 psi.

That is why all brake fittings are flare type fittings. These parts are attached to each other by first sliding the nut onto the tube or pipe and then connecting the compression ring. The compression fitting is comprised of a nut and a ferrule.

How reliable are compression fittings. Unfortunately using brake line compression fittings presents multiple problems. Compression nuts are threaded meaning that the number of rotations of the nut is directly correlated to the linear compression of the ferrule based on the threads pitch.

The compression fitting is comprised of a nut and a ferrule. Compression fittings are used to join two pieces of brake line together. These fittings arent normally used in new constructions but rather renovation projects.

This form of repair is common because of the idea that the fitting prevents leakage. Compression fittings are ingenious because you can use them in places where welding isnt an option. Also compression fittings can be used on leaky pipes such as broken water lines in an emergency situation.

Compression fittings are used to join two pieces of brake line together. We have the best Compression Fitting for the right price. This form of repair is common because of the idea that the fitting prevents leakage.

Additionally are brake line compression fittings legal in Ontario. During temporary maintenance compression fittings can also be used to repair brake lines. Particularly on a cut line the brake fluid will cause corrosion over time.

Under a panic stop that can double. When placed on a brake line the fitting creates a tightened joint. Compression fittings are used to join two pieces of brake line together.

When placed on a brake line the fitting creates a tightened joint. In general these fittings are made up of three components. A compression fitting compresses a component of the fitting into another component usually some type of tubing to create a watertight seal between two different lines.

Once corrosion causes the line to weaken it will fail.

Bmw E53 X5 Brake Line Failure Common Issue European Auto Repair Tampa Eurospeed Automotive

How To Use Compression Fittings

Compression Fitting Union 1 4 In 785 304d Advance Auto Parts

How To Connect Brake Lines With New Fittings A Union Youtube

Splicing Brake Line Compression Fitting Killing Me Tccoa Forums

Top 3 Reasons Not To Use Brake Line Compression Fittings Brakeconnect

Tom S Vw Pages Steel Brake Line Repairs

Brake Line Repair When To Use A Compression Fitting Doityourself Com

How To Use Brake Line Fuel Line Compression Fittings What They Look Like How To Use Them Youtube

Brake Line Repair Tubing Fittings

How To Fix Leaky Brake Line Fittings

Confused By Brake Line Fittings Factory Five Racing Forum

How To Replace Brake Hose And Line Cutting Flaring And Bending Youtube

Tom S Vw Pages Steel Brake Line Repairs

Top 3 Reasons Not To Use Brake Line Compression Fittings Brakeconnect

Flare Lapping Tool Brake Fuel Lines Koul Tools